Blog

Cash is king! How modern software makes quick and sustainable savings possible

Cash is king! How modern software makes quick and sustainable savings possible

Cash is king! How modern software makes quick and sustainable savings possible

A call late Friday afternoon: „We need to write to our suppliers and demand discounts – we’re going to have a real cash problem in the upcoming quarters!“

Cost savings with suppliers that can be implemented quickly and remain sustainable? That’s not possible, it takes months to negotiate!

Indeed, renegotiating contracts with suppliers takes months and there is no guarantee that it will be successful in the end. But the pressure on material costs has never been higher than during Covid19. How can a modern analytics platform help realize fast and sustainable cost savings?

1. re-think your existing data!

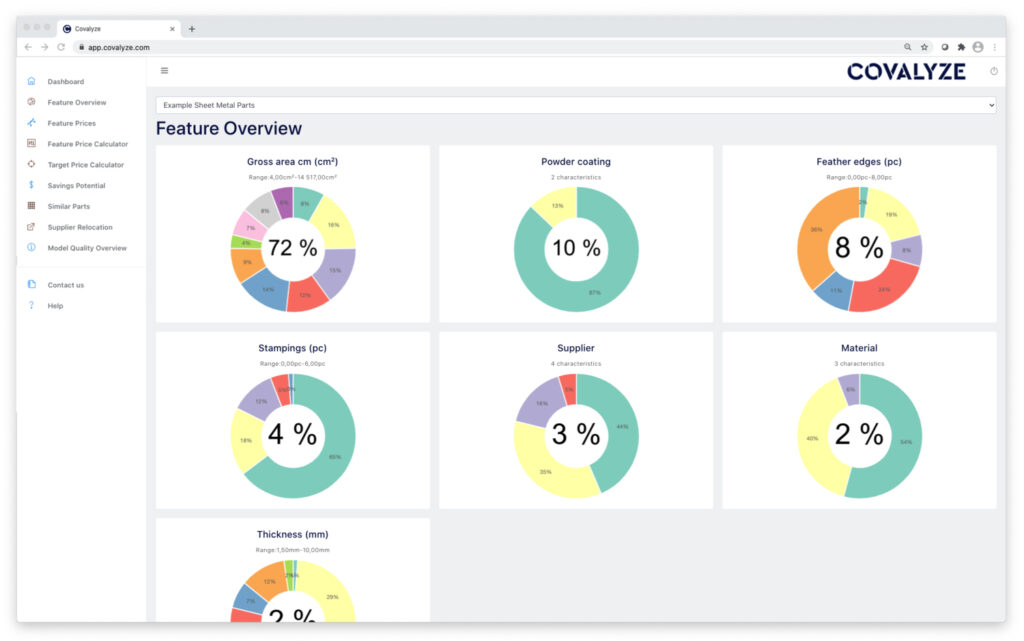

The first step is the most difficult and at the same time the easiest! Your purchasing data is already structured by commodity groups and suppliers. What is missing is the link to the technical documents! These contain valuable data that you have barely used for an entire material group before. By combining technical parameters and the prices of the various parts of a material group, you can determine cost drivers with the help of machine learning models and thus have high-quality data models that allow a variety of new and powerful cost reduction levers! However, the following lever still works the fastest:

2. replace high volume parts with lower cost designs!

Nothing works faster than replacing expensive parts with existing alternatives. You think you have already done that? Certainly not for those parts that are highly variant-driven and of which you purchase dozens (or even hundreds) of similar parts: Packaging, metal parts, electronics parts. Here, as we all know, the devil is in the details: a cheap packaging is 2mm higher than the more expensive design? A bent steel part has 2 holes less than the more expensive design? Not only do we find identical parts with different part numbers, we especially find many „similar parts“, some of which have significant price differences to the high volume parts. But when you discuss the differences with engineering based on clear data, decisions often go much faster!

3. Don’t forget additional quantity effects!

Nothing goes faster than using existing parts and suppliers to replace designs that are too expensive. No additional supplier qualification, no new quality checks for volume production. But there is often one crucial hurdle: Can the supplier deliver the higher quantities permanently? If so, then you even have an additional trump up your sleeve: additional savings through bundling!

Modern software not only saves time and staff effort in preparing analyses, it saves above all on material costs, which often account for 50% or more of a company’s cost structure. The faster a price reduction can be implemented on part level the faster you will see the cash effects. Our implementation time from initial data collection to concrete identification of quickly realizable savings takes 3-4 weeks. Try us, we will help you to massively accelerate your cash-effective savings!

Five unique reasons, why your teams will negotiate better

Why Reliable Price Prediction Should Be

26/10/2022

I still remember a project in my time as a consultant, when the responsible buyer said that one should NOT negotiate in his commodity group at the …

„Bytes Beat Metals“ – Or Why The Cost

26/10/2022

I am putting three articles/posts on your heart today that have particularly impressed me in the last few days: Top 25 car makers by market cap …

How Can Purchasing Become More

26/10/2022

Yesterday, I had the opportunity to have a lengthy conversation with the CPO of a global machine tool manufacturer. When …